-

PERFORMANCE

- · Designed panels provide as close fit as possible to the pipe or vessel being insulated. This means that on vertical risers the design severely restricts any “chimney effect” convection in the air gap between the pipe surface and the inner skin.

- · Darmet is an assembly of thin gauge stainless steel foils in factory made cassettes, which have been specifically designed to minimize heat loss that occurs through conduction, convection and radiation.

-

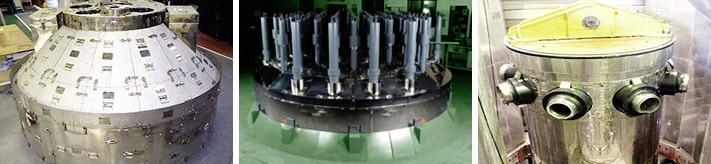

DARMET

- · DARMET is a fully engineered all metallic construction in austenitic stainless steel with excellent performance characteristics.

-

FUNCTION

- · Reduced heat loss, low air temperature in storage buildings, and less difficulty in equipment operation occur less frequently.

- · It offers insulation performance, strength and structural aspects, and detachability.

- · It possesses multifunctional capabilities such as durability until the completion of the power plant's lifespan without environmental or user health and safety concerns.

-

PRINCIPAL FEATURE OF DARMET

- · Removability and Replacement

- - Being an engineered system, the ease of removability and replacement of Darmet can be varied in accordance with the requirements of a particular application.

- - For in service inspection or maintenance, the panels can be designed so that they can be removed in less than a minute. This rapid operation reduces radiation exposure times, reduces labor and material costs and down time of equipment.

- - Darmet does not become radioactive when irradiated, making disposal easier at the end of the plants life.

- · Corrosion Resistance

- - The Darmet system is generally constructed from austenitic stainless steel.

- - Darchem Engineering has not encountered any situation where it has corroded in nuclear environments.

- - Darmet has been installed for more than 30 years in some plants.

- - Darmet does not contain any chloride ions and therefore does not initiate stress corrosion cracking.

- · No Health Risk

- - Darmet all-metallic insulation contains no fibres and therefore does not contribute to the risks associated with the ingestion of contaminated airborne particles by maintenance personnel. (Within some countries fibrous insulation materials are considered to be a class 2 carcinogen.)

- · Drain ability

- - The exterior of Darmet is water shedding. It is self-draining. Its thermal performance is therefore unaffected by water and does not hold chloride in contact with the pipework, unlike fibrous insulation which quickly slumps when wetted.

TEST (REQUIREMENTS OF BSI/BS EN ISO 9001:2015)

A key advantage of Darmet is its lightweight individual panel system as the basic configuration, allowing for swift disassembly and reinstallation, thus minimizing reactor downtime. This reduces outage time caused by reactor shutdown, leading to minimized expenses for maintenance and construction costs.

- · Thermal performance on representative large scale vessel areas.

- · Thermal performance of large and small bore pipework in various orientations.

- · Mechanical shock up to 300g.

- · Measurement of effect on thermal performance of ageing and contamination.

- · Panel robustness.

- · Drainage and water spray.

- · Seismic accelerations up to 5G.